Today, of course, you might be more used to seeing copper’s electrical applications through the use of power lines, telephone wires, and wiring in practically every major home appliance you own. Millions of tons get used for these applications every year, but it is still early days for copper’s use in electrification. That’s because copper will continue to be a critical component of the green energy revolution, thanks to the rising adoption of battery-powered vehicles.

Why Copper?

Today’s visualization comes to us from Canadian Platinum Corp., and it focuses on showing how much copper is in an electric vehicle, along with the properties that make it the ideal choice for an EV-powered future. Here is why copper is a crucial component to vehicle manufacturers: Cost Copper costs roughly $0.20 per ounce, compared to silver ($15/oz) and gold ($1200/oz), making it by far the cheapest option for electrical wire. Conductivity: Copper is nearly as conductive as silver – the most conductive metal – but comes at a fraction of the cost. Ductility: Copper can easily be shaped into wire, which is important for most electrical applications. It’s also important to note that temperature does not affect copper’s conductivity, which makes the metal ideal for automobiles in all climates.

Copper in Gas vs. Electric Vehicles

The UBS Evidence Lab tore apart a traditional gas-powered vehicle as well as an EV to compare the different quantities of raw materials used. What they found was crucial: there is 80% more copper in a Chevrolet Bolt, in comparison to a similar-sized Volkswagen Golf. The major reason for this is that at the heart of every EV is an electric motor, which is built with copper, steel, and permanent magnets (rare earths). Electric motors tend to be much simpler than gas-powered engines, which have hundreds of moving parts. Incredibly, in an electric motor, there can be more than a mile of copper wiring inside the stator.

The More Electric, the More Copper

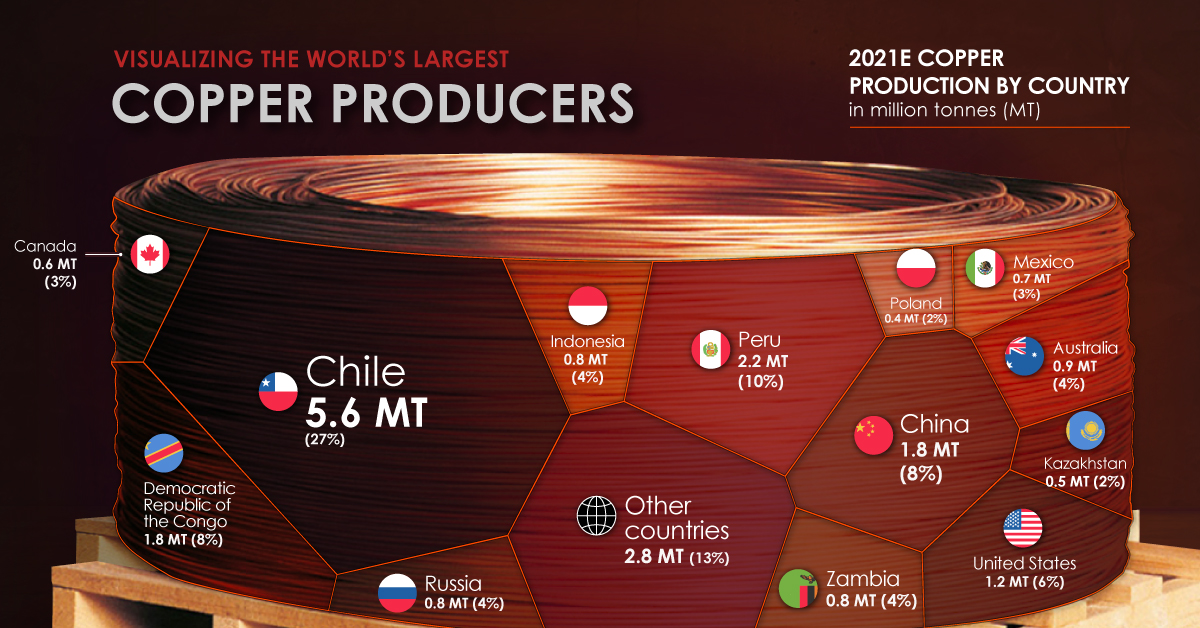

According to Copper.org, along the scale from gas-powered cars to fully electrical vehicles, copper use increases dramatically. Conventional gas-powered cars contain 18 to 49 lbs. of copper while a battery-powered EV contains 183 lbs. Meanwhile, for a fully electrical bus, a whopping 814 lbs. of copper is needed. With the rapidly increasing adoption of electric vehicles, copper will be an essential material for the coming electrification of all forms of ground transport. Copper is at the heart of the electric vehicle and the world will need more. By 2027, copper demand stemming from EVs is expected to increase by 1.7 million tonnes, which is a number just shy of China’s entire copper production in 2017. on Man has relied on copper since prehistoric times. It is a major industrial metal with many applications due to its high ductility, malleability, and electrical conductivity. Many new technologies critical to fighting climate change, like solar panels and wind turbines, rely on the red metal. But where does the copper we use come from? Using the U.S. Geological Survey’s data, the above infographic lists the world’s largest copper producing countries in 2021.

The Countries Producing the World’s Copper

Many everyday products depend on minerals, including mobile phones, laptops, homes, and automobiles. Incredibly, every American requires 12 pounds of copper each year to maintain their standard of living. North, South, and Central America dominate copper production, as these regions collectively host 15 of the 20 largest copper mines. Chile is the top copper producer in the world, with 27% of global copper production. In addition, the country is home to the two largest mines in the world, Escondida and Collahuasi. Chile is followed by another South American country, Peru, responsible for 10% of global production. The Democratic Republic of Congo (DRC) and China share third place, with 8% of global production each. Along with being a top producer, China also consumes 54% of the world’s refined copper.

Copper’s Role in the Green Economy

Technologies critical to the energy transition, such as EVs, batteries, solar panels, and wind turbines require much more copper than conventional fossil fuel based counterparts. For example, copper usage in EVs is up to four times more than in conventional cars. According to the Copper Alliance, renewable energy systems can require up to 12x more copper compared to traditional energy systems. With these technologies’ rapid and large-scale deployment, copper demand from the energy transition is expected to increase by nearly 600% by 2030. As the transition to renewable energy and electrification speeds up, so will the pressure for more copper mines to come online.